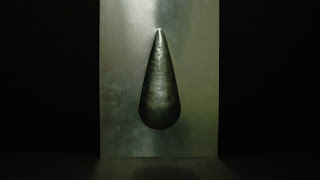

The Blister

The Blister

Wood Sheet used: 11

Process

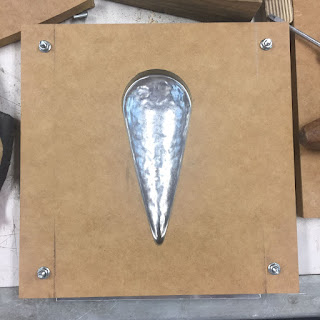

Cutting the metal sheet into 22cm*29cm size to fit in between the 4 screws.

Prepare 3 type of cocking tools as

shown below, for hammering the edge of the metal sheet which a mallet cannot normally reach.

Wood Sheet used: 11

Process

Cutting the metal sheet into 22cm*29cm size to fit in between the 4 screws.

Prepare 3 type of cocking tools as

shown below, for hammering the edge of the metal sheet which a mallet cannot normally reach.

Top for focus point hammering

Middle for flattening the surface

Bottom for sharp edges

Secure the metal sheet with 4 screwed as shown below

Hammer the edge of the metal sheet, in the beginning, to fix the shape and boundary of the blister by using the top and bottom tool

Use the combination of mallet and top tool smartly to hammer the desired depth of the blister

Put the metal sheet on a sandbag occasionally to smoothen the surface as the top will create many shapes and unwanted form on the surface

The process took less than 2 hours.

The results are below.

Comments

Post a Comment